| Engine Services |

| e-mail us |

| Contact us |

|

|

|

|

|

||||||

Click here to email Ard Racing or Telephone/Fax +44 (0)191 261 4579 Cylinder bores are second only to the crankshaft in their effect on the performance of your engine. Strangely, they are also probably the most underestimated and abused part. The number of times engine builders will examine a cylinder, or at best run an 'experienced' finger over the surface and mutter 'Yeah, they'll do' is amazing |

||||||||||

|

|

||||||||||

|

Your eye might tell you the bore is nice 'n shiny. Your finger will tell you it is nice 'n smooth. But how do you know it is still round and not slightly oval? Is the piston to bore clearance within tolerance? Is it even the same (i.e. parallel) all the way down? That tiny scratch all the way down the bore may look totally insignificant, but it will still reduce compression by letting the compressed gases escape past the rings. What about checking piston ring land wear, ring end gap or on a two-stroke, the ring peg? |

||||||||||

|

||||||||||

|

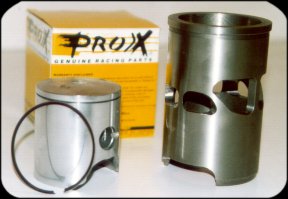

First of all, we don't care whether the motor will lap your back garden in your lawn mower, or lap the Isle of Man, they are all done to the same standard. We use only high quality pistons from people like Wiseco and Prox. (O.K., Wiseco don't do many lawn mower pistons, but you get the idea!) All new pistons are carefully measured before we begin. This allows us to set up the boring machine to ensure that the correct piston to bore clearance will be achieved rather than simply believing the size stamped on the piston. Remember, like most things these days, pistons from even the best manufacturers are mass produced to tolerances. The differences may be small, but they are there.

|

||||||||||

|

||||||||||

|

All four of our boring machines are maintained in first class order by careful and regular servicing. You cannot bore a cylinder to correct tolerances if the spindle bearings in the machine are worn.

Once the cylinder is removed from the boring machine, all two stroke barrels receive careful attention to their ports to ensure that all edges are de-burred and chamfered to factory spec.

Our workshop runs to only one standard. A very high standard. Why? Because a compliment from a customer feels much better than punch on the nose! Joking aside, all work that passes through our workshop is treated to the same high standard of care. |

||||||||||

|

||||||||||